GraceSense Hot Spot monitor

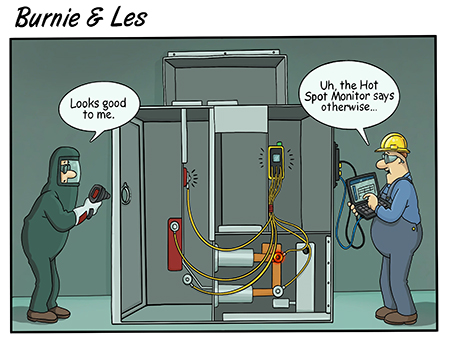

Continuous temperature monitoring in real time can detect potential hot spots or overheating in electrical equipment. Identifying possible faults before they occur minimize downtime, unplanned interruptions and above all - saves money.

Hot spots, overheating and overload in electrical equipment may cause fire or production interruptions. A common method to identify overheating issues is thermography with an IR camera. Thermography gives a snapshot of the electrical equipment and it is not always possible to access all areas.

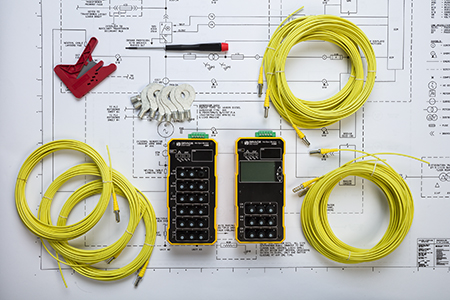

One alternative that gaining more attention lately is continuous temperature monitoring. GraceSense Hot Spot Monitor use a non-conductive polymer based sensor on a ring lug, fitted direct on the joint that should be supervised. It is now possible to identify hot spots and overheating, data is logged in the main unit. Alarms and logging intervals can be configured via a web based interface, data can also be extracted.

GraceSense Hot Spot Monitor also offers plant-wide integration via Modbus TCP/IP or EtherNet/Ip communication.

The system can be used to supervise

- Low and medium voltage switchgear

- Distribution switchgear

- Larger UPS, battery systems

- Busbars

- Motors, generators

- Transformers

GraceSense Hot Spot Monitor is available with 9 alternatively 18 sensors/channels and are supplied with 10m long sensors, other lengths on request

For more information, contact one of our

PRODUCT SPECIALISTS